Cutting edge technology

Mantec are precision engineering specialists based in Manchester

Get in touch for a quoteFrom revolutionary projects to critical maintenance, the acutely high-risk and challenging operational environments of sub-sea, oil and gas demand Mantec’s technologically advanced and durable components for performance and assurance.

DETAILSWe manufacture precision engineered components of uncompromising quality for the rail industry. All our work is engineered to the highest standards and delivers steadfast performance in the face of continual usage and stress that rail networks demand.

DETAILSAdvanced machining technology guarantees robust, reliable components. Earth moving equipment manufacturers choose Mantec to ensure vehicles operate at full capacity and deliver an extended lifespan.

DETAILSMeticulous processes and time-served engineers deliver accurate components engineered to the strictest tolerances. Cutting edge technology accelerates the manufacturing process, meaning that Mantec can deliver accurately and quickly.

DETAILSUnmatched risk and volatility make nuclear a particularly challenging industry. Our advanced precision engineering delivers components of uncompromising performance and reliability to withstand extreme, highly-specialised conditions.

DETAILSThe latest technology, a state-of-the-art facility and quality approvals make Mantec a trusted partner to the highly-regulated food sector. Components are engineered in controlled environments to short timescales and in high volumes.

DETAILSDefence equipment must perform under all circumstances. Mantec’s advanced capabilities ensure that exacting specifications are met for components deployed in some of the world’s most advanced national security technology and equipment.

DETAILSMantec’s precision engineering delivers the highest quality, most precise and durable custom components for the demanding chemicals industry. With the consequences of equipment failure being so great, only the very best is accepted.

DETAILS

Mantec are precision engineering specialists based in Manchester

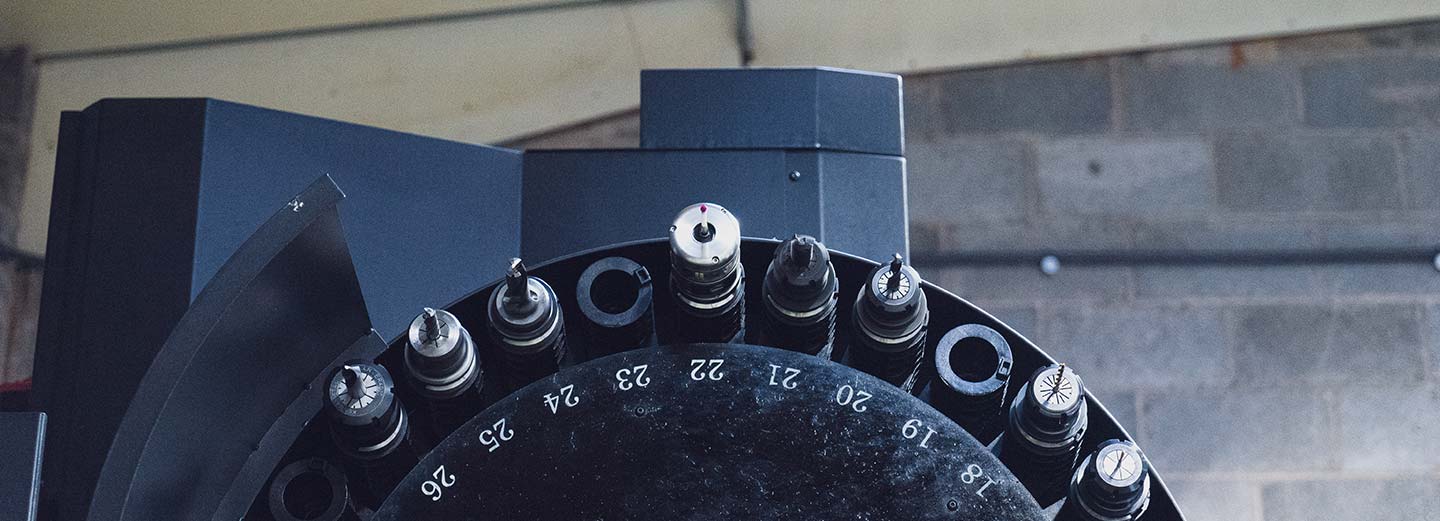

Get in touch for a quoteWith a wide range of both horizontal and vertical milling machines from Doosan and Daewoo, our milling capability allows us to manufacture components to extremely high standards.

Twin pallet capacity machines enable the production of complex parts in a single machine, saving time and money for our customers.

Our turning centres are the ultimate CNC tool for multi-tasking. With three 9 axis turning centres and two 8 axis turning centres, our goal is to be able to machine extremely complex parts without the need for secondary handling or machines to complete the manufacturing process.

Our approach means better quality, greater consistency and higher throughput, all of which offer considerable benefits to our customers.

Our high specification milling and turning machine capacity allows Mantec to offer CNC prototyping services for a number of industry sectors. Typically we are called on to create components from robust materials after 3D modelling has shown that a component has been designed correctly, but now needs to demonstrate fitness for purpose.

Quality is paramount and we work hard to ensure customer satisfaction. Many of the components we produce have GD&T requirements that can only be verified efficiently by use of CMM and we invest in the latest metrology equipment to inspect.

All gauging used is calibrated to UKAS standards and managed through caliso calibration software to ensure accuracy and traceability. We are ISO 9001 accredited and are audited annually by NQA, but also welcome independent audit by our customers to ensure satisfaction with our manufacturing and quality procedures.

On site assembly and production capability means we can finish and assemble your components ready to ship for a complete service.

We also offer a variety of surface finishes including anodizing to suit your requirements.

To discuss a project or for more information about our experience and technologies, please complete the form and we will get back to you shortly.